Authors

Christopher Sacco, Anis Baz Radwan, Andrew Anderson, Ramy Harik, Elizabeth Gregory

Journal

Composite Structures, 250, 112514.

Abstract

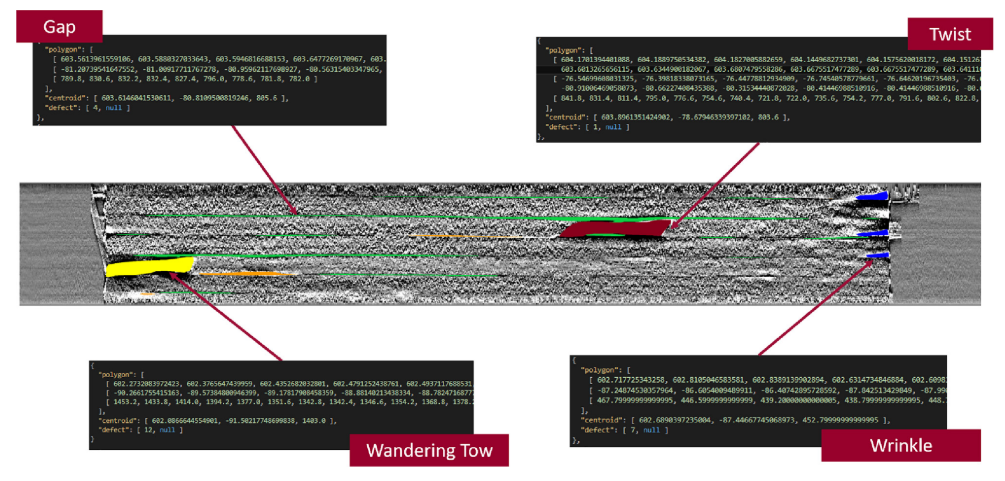

The large-scale adoption of composite materials in industry has allowed for a greater freedom in design and function of structures and their respective components. However, the freedom of material choice has resulted in increased complexity in manufacturing. Machine learning (ML) and Artificial Intelligence (AI) are currently being explored for a number of advanced manufacturing applications, and their applicability has begun to extend into the composites manufacturing realm. In this document, a comprehensive overview of machine learning applications in composites manufacturing will be presented with discussions on a novel inspection software developed for the Automated Fiber Placement (AFP) process at the University of South Carolina utilizing an ML vision system. This vision system allows for defect data to be fully integrated into the manufacturing process, allowing for the ML inspection system to influence several chains in the composites product lifecycle management.

Keywords

automated fiber placement, inspection, machine learning

Citation

Christopher Sacco, Anis Baz Radwan, Andrew Aderson, Ramy Harik, & Elizabeth Gregory. (October 2020). Machine Learning in Composites Manufacturing: A Case Study of Automated Fiber Placement Inspection. Composite Structures, 250, 112514. doi:https://doi.org/10.1016/j.compstruct.2020.112514

Link: https://www.sciencedirect.com/science/article/pii/S0263822320313659

Documents